Grain machine Chain used in grain and oil machineries have two structures, one is roller chain, and the other is welded cranked link chain. Chains of such two structures can be flexibly fit with various accessories, so as to meet diversified needs of the grain and oil processing and production lines.

Standard Model number:LTF665/LTF100/LTF1100 Conveyor chain for grain machine.Also have our own model number as below:LJ665 Conveyor chain and other specifications.

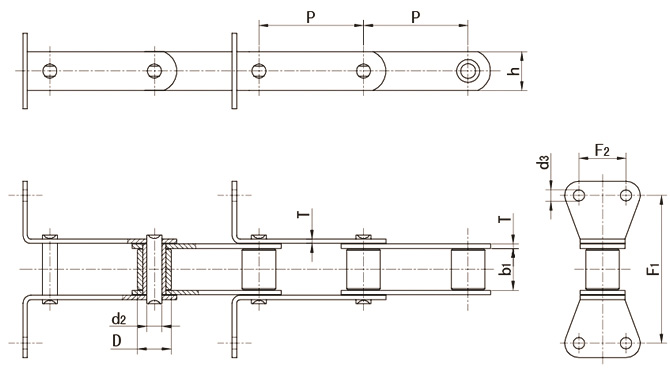

| CHAIN No. | Pitch | Roller dia. | Width between inner plate | Pin dia. | Plate depth | Plate Thickness | Dimensions of Scraper | Avg Ultimate Tensile Strength | ||

| P | D | b1 | d2 | h | T | F1 | F2 | d3 | Q | |

| mm | mm(max) | mm(min) | mm(max) | mm(max) | mm(max) | mm | mm | mm | KN | |

| LJ60 | 60 | 22.3 | 25.22 | 11.1 | 30 | 5 | 102 | 32 | 10 | 124 |

| LJ68 | 68 | 22.3 | 25.22 | 11.1 | 29 | 4.8 | 102 | 32 | 9 | 70 |

| LJ655/5 | 66.5 | 22.3 | 26.5 | 12 | 30 | 5 | 102 | 32 | 10 | 100 |

| LJ655 | 66.5 | 22.3 | 26.5 | 12 | 30 | 6 | 102 | 32 | 10 | 124 |

| TGSU20/25 | 60 | 22.3 | 26 | 12.7 | 30 | 6 | 102 | 32 | 10 | 124 |

| LJ762 | 76.2 | 22.3 | 25.22 | 11.1 | 30 | 5 | 102 | 32 | 9 | 124 |

| TGSU32 | 80 | 28 | 32 | 18 | 42 | 6 | 120 | 32 | 9.5 | 169 |

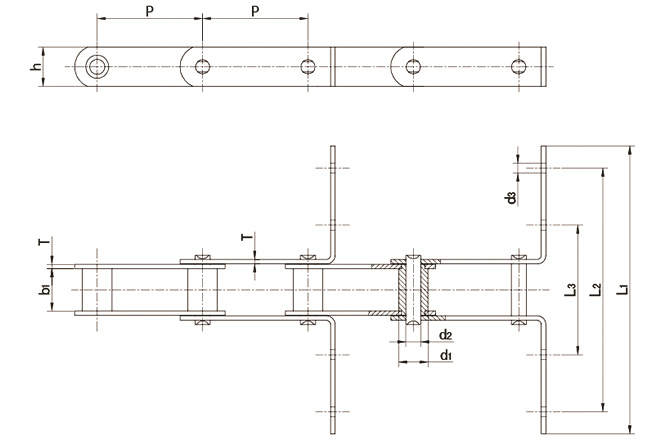

| CHAIN No. | Pitch | Roller dia. | Width between inner plate | Pin dia. | Plate depth | Plate Thickness | Dimensions of Scraper | Avg Ultimate Tensile Strength | |||

| P | d1 | b1 | d2 | h | T | L1 | L2 | L3 | d3 | Q | |

| mm | mm(max) | mm(min) | mm(max) | mm(max) | mm(max) | mm | mm | mm | mm | KN | |

| LJ66.5D | 66.5 | 22.23 | 26.5 | 12 | 30 | 6 | 6 | 102 | 14×9 | 124 | |

| LJ66.HC | 66.5 | 22.23 | 26.5 | 12 | 30 | 6 | 2 | 113.75 | 102 | 14×9 | 124 |

| TGSS20 | 66.675 | 22.23 | 26 | 12.7 | 30 | 6 | 8 | 154 | 90 | 9.5 | 124 |

| TGSS25 | 66.675 | 22.23 | 26 | 12.7 | 30 | 6 | 1 | 195 | 95 | 9.5 | 124 |

| TGSS32 | 66.675 | 22.23 | 26 | 12.7 | 30 | 6 | 95 | 195 | 95 | 9.5 | 124 |

| LF6668 | 66.68 | 22.23 | 25.22 | 11.1 | 29 | 4.8 | 60 | 136 | 80 | 7 | 124 |

| LJ68DK | 68 | 22 | 25.5 | 9.5 | 23 | 4 | 14 | 80 | 7 | 49 | |

| LJ68SK | 68 | 22.23 | 25.22 | 11.1 | 29 | 4.8 | 5.5 | 136 | 80 | 7 | 124.6 |

| TGSS40 | 125 | 32 | 50 | 19.9 | 50 | 8.0 | 285.0 | 265.0 | 155.0 | 9.5 | 222.4 |

| TGSS50 | 125 | 32 | 48 | 19.9 | 50 | 10.0 | 358.0 | 310.0 | 170.0 | 9.5 | 222.4 |

| TGSS63 | 200 | 50 | 52.0 | 23.8 | 70.0 | 10.0 | 610.0 | 510.0 | 230.0 | 11.0 | 315.0 |

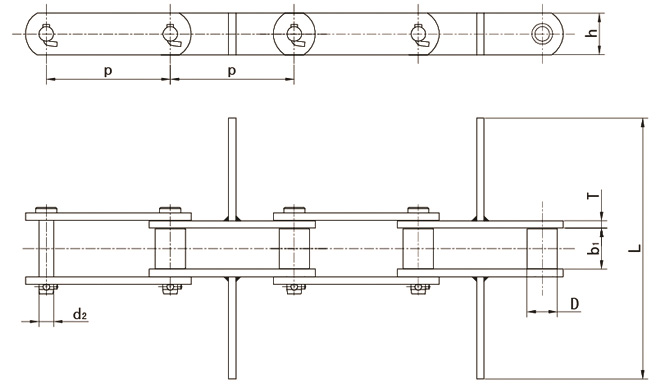

| Pitch P mm | Inner Width of inner Link b1(min) mm | Dimension of Roller D(max) mm | Dimension of Pin d2 mm | Height of Sidebar h mm | Thickness of Sidebar T mm | Width of Scraper L mm | Tensile Strength Q (min)KN |

| 101.6 | 31.75 | 31.75 | 15.8 | 50 | 8 | 154 | 138 |

| 152.4 | 52 | 40 | 19.1 | 60 | 8 | 188 | 158 |

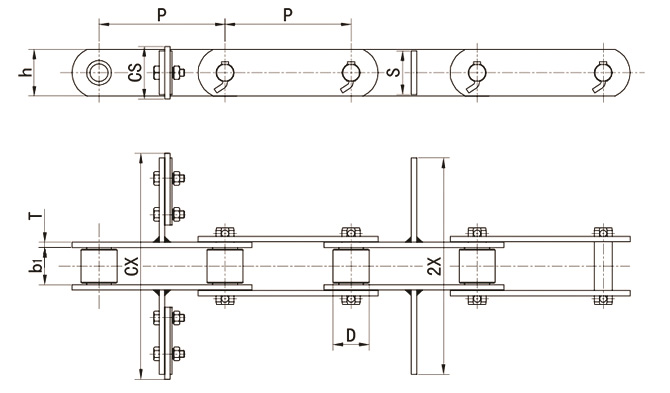

| CHAIN No. | Pitch P | AVG Ultimate Tensile Strength (kgf) | Weight (kg/m) | Roller | Inner width | Chain Plate | Scraper | Plastic Scraper | |||

| R | W | h | T | 2X | S | CX | CS | ||||

| DS 03075S | 75 | 3000 | 2.1 | 15.9 | 16.1 | 22 | 3.2 | 95 | 20 | 105 | 28 |

| DS 430S | 101.6 | 5500 | 3.4 | 20.1 | 22.6 | 25.4 | 4.8 | 135 | 22 | 145 | 32 |

| DS 450S | 101.6 | 8000 | 5.0 | 22.2 | 27 | 28.6 | 6.3 | 135 | 25 | 145 | 34 |

| DS 08125S | 125 | 8000 | 5.0 | 22.2 | 27 | 28.6 | 6.3 | 185 | 25 | 195 | 34 |

| DS 10125S | 125 | 11500 | 6.8 7.3 | 29 | 30 | 38.1 | 6.3 | 185 225 | 34 | 195 235 | 47 |

| DS 10150S | 150 | 11500 | 6.9 7.2 | 29 | 30 | 38.1 | 6.3 | 250 300 | 34 | 265 315 | 47 |

| DS 6205S | 152.4 | 19000 | 10.5 | 34.9 | 37.1 | 44.5 | 7.9 | 250 | 40 | 265 | 53 |

| DS12200S | 200 | 19000 | 10.3 | 34.9 | 37.1 | 44.5 | 7.9 | 330 | 40 | 345 | 53 |

| DS 17200S | 200 | 25000 | 14.0 16.0 | 40.1 | 51.4 | 50.8 | 9.5 | 330 430 | 46 | 345 445 | 58 |

| DS 26200S | 200 | 32000 | 21.0 | 44.5 | 57.2 | 63.5 | 9.5 | 430 | 58 | 445 | 68 |